| [ Improving a Thorens TD 318 ] |

© Ernest Ruiz , 2015

This article that you are beginning to read is perhaps the one that has taken the longest time to write. This is due to the lack of time I have for my audiophile activities.

The project of improving the Thorens TD 318 began in 2006 when I bought the turntable and it was stopped until 2014 when the work was finished. The refurbishing process itself took two months and during this time many changes were made to the turntable: structural modifications, replacement of parts and the final assembly. All of them to enjoy a better turntable, even better that it was new.

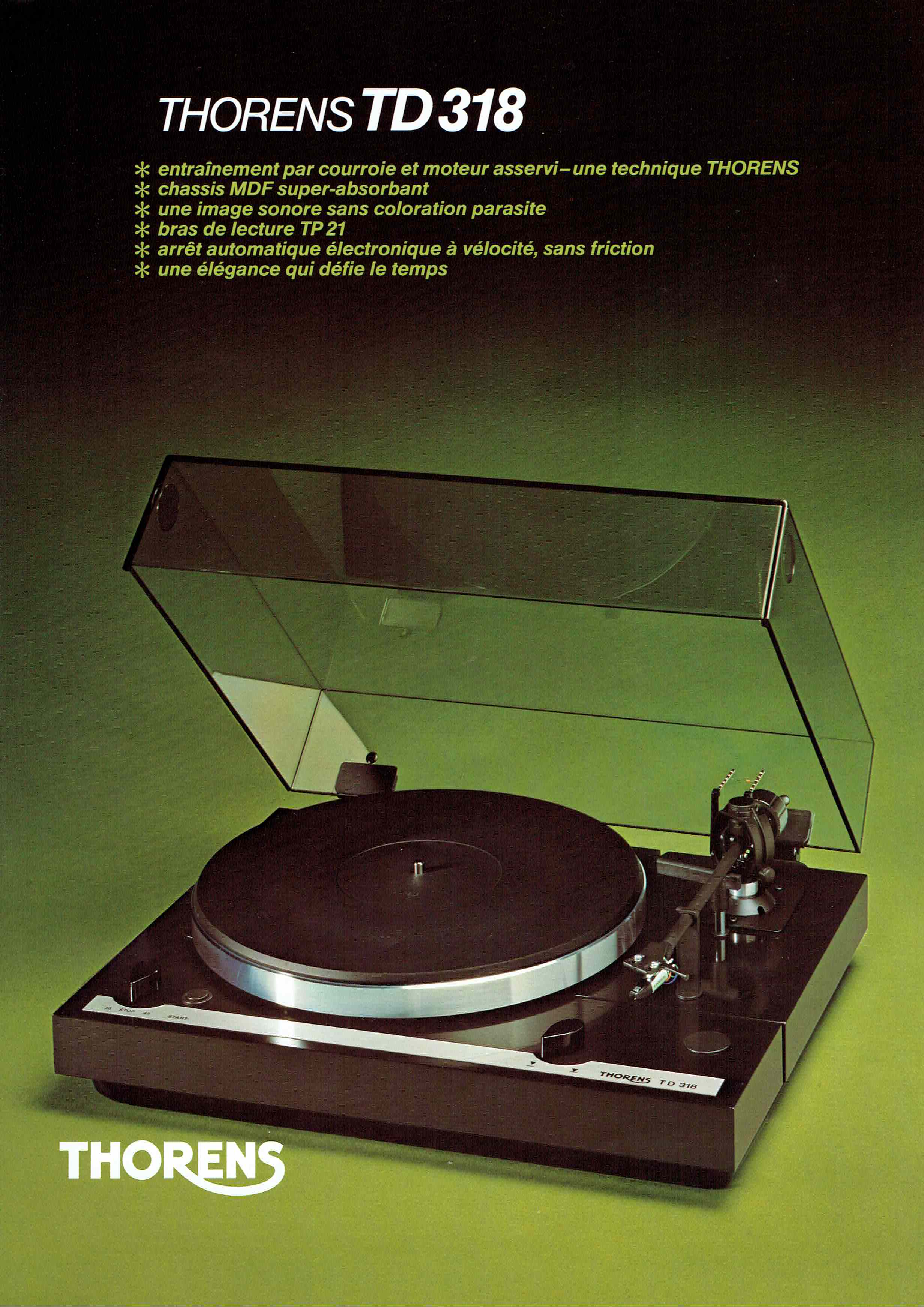

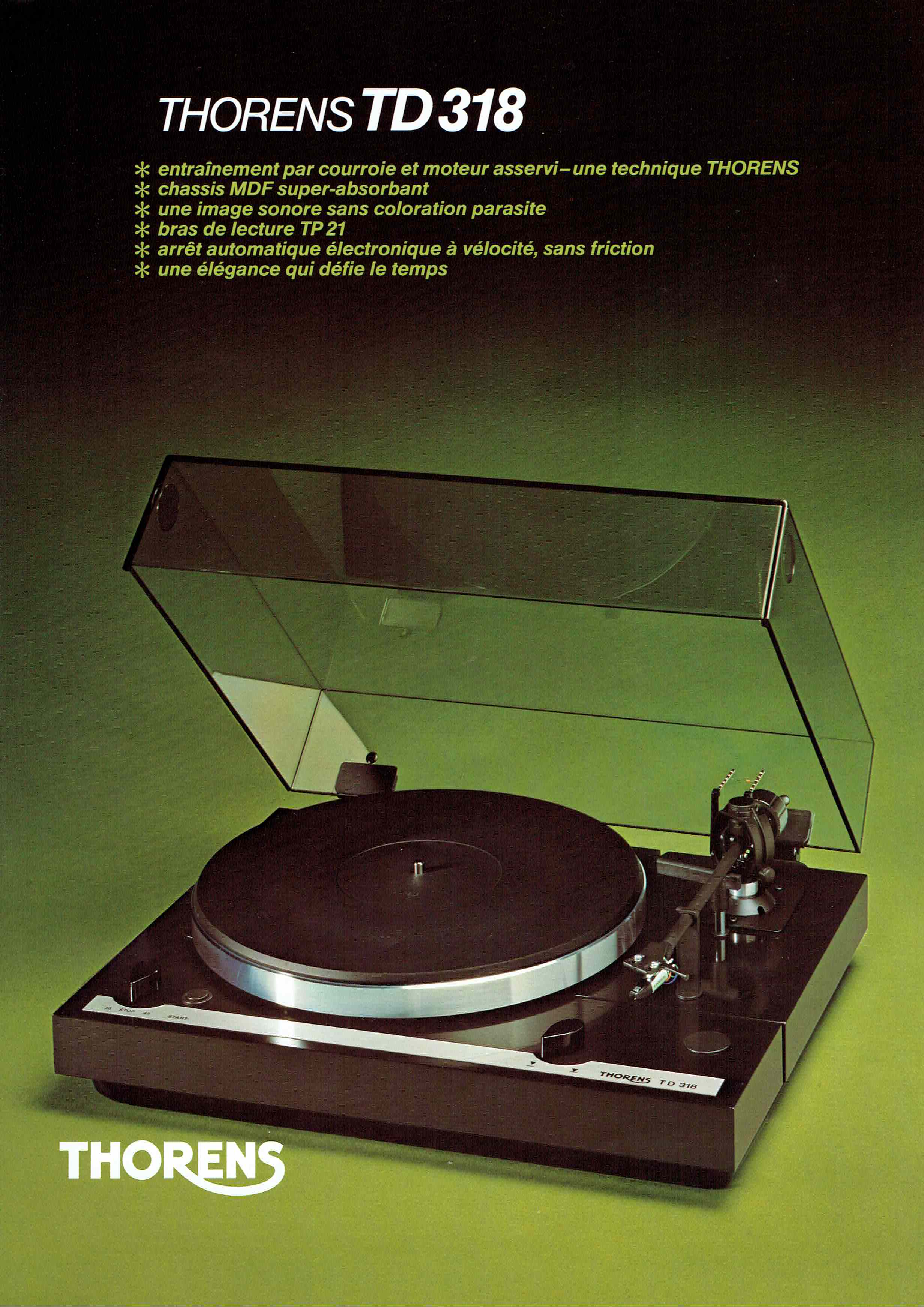

The Thorens TD 318 is a semi-automatic two-speed belt-driven turntable that was made by the swiss company form 1985 to 1991, when vinyl was in its full decline. The design of the TD 318 follows the classical model of a suspended sub-chassis system invented by Edgar Villchur and that was first sold in 1961 by Acoustic Research in its XA model. Thorens began to use this concept of suspended sub-chassis in 1965 with the TD 150, as Ariston did in 1971 with the RD11 and Linn from 1972 with the Sondek or LP12 .

When the TD 318 was available for purchase by customers it was part of the 300 series of Thorens turntables, the middle range of their vinyl playback systems, and shared its existence with the 100, 200 and 500 series. In the 300 series it was the mid-level turntable, with the TD 316 below and the TD 320-321 above. In respect to the lower model, the TD 318 had auto-off, automatic tonearm lift and used a Thorens TP 21 tonearm instead of the TP 28 fitted to the TD 316. The differences between the TD 318 and the TD 320-321 were in the sub-platter and the tonearm. The mid-level model used a plastic sub-platter meanwhile the TD 320 used a metallic one and a TP 90 tonearm and the TD 321 was sold without tonearm in order to allow the user to choose any option available in the market (mainly the SME 3009 tonearm). According the data available at Vinyl Engine about the TD 318 its specifications are as follows:

When I decided to began this project I has some ideas in mind. First, the system to choose for the improvement process should be a well known system, reliable and solid. Second, it should be easy to modify and it had to react positively to the modifications. Also, it had to be easy to purchase in the second hand market for a reasonable amount of money. With all these ideas in mind the obvious choice was a Thorens turntable. I could have bought many other models from the swiss manufacturer, for instance the manual 2 speed belt-driven TD 160 or TD 166, or even a model form the 200 series. Maybe today, I would choose a TD 320-321 or a TD 520-521, although they will compromise the cost requirements.

The changes I wanted to do in the turntable were:

The process began with the disassembling of the original tonearm and all its electrical connections and the disassembling of the metal base of the turntable to which the self-adhesive sound deading pads were applied. With this modifications the mass of the turntable is increased as it is the isolation because unwanted resonances are eliminated.

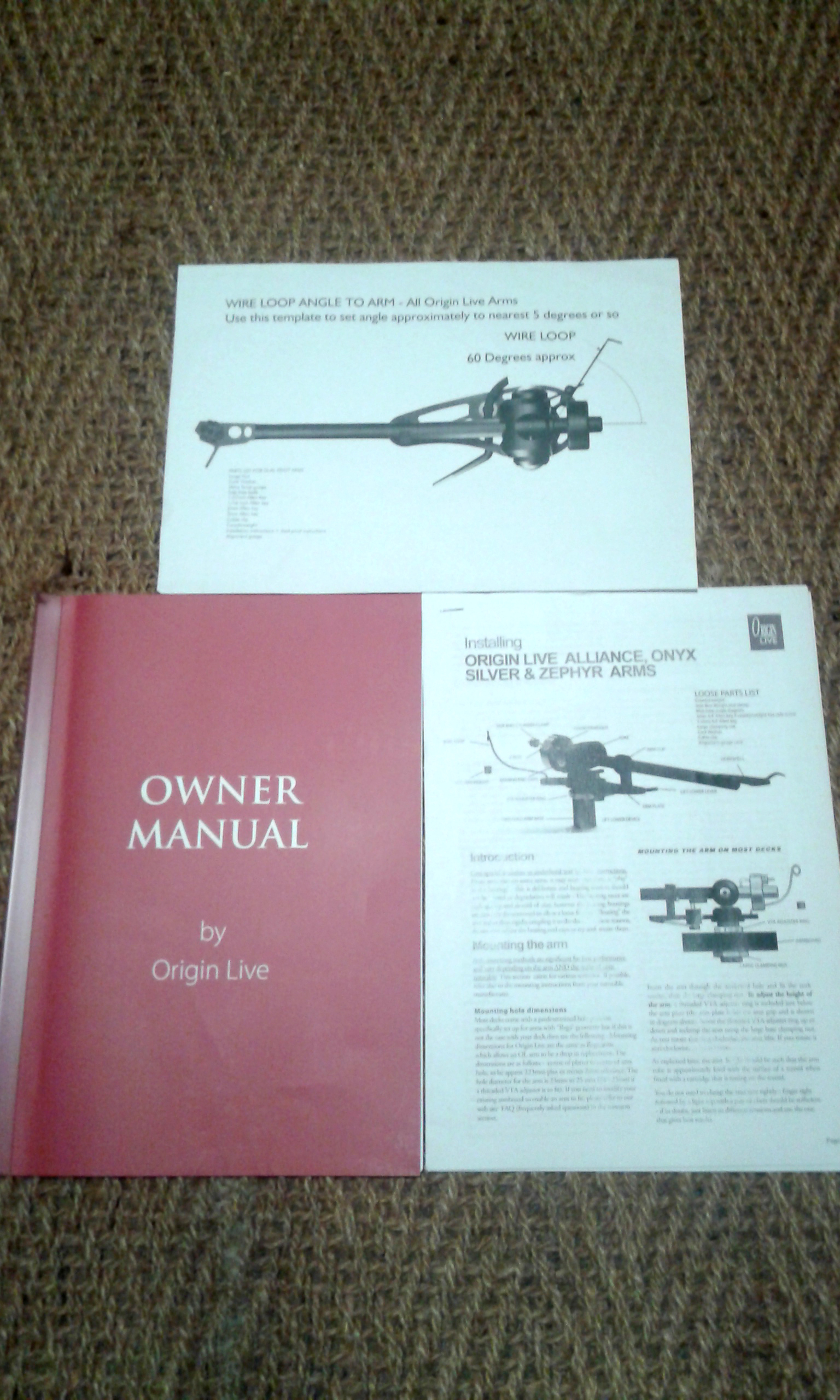

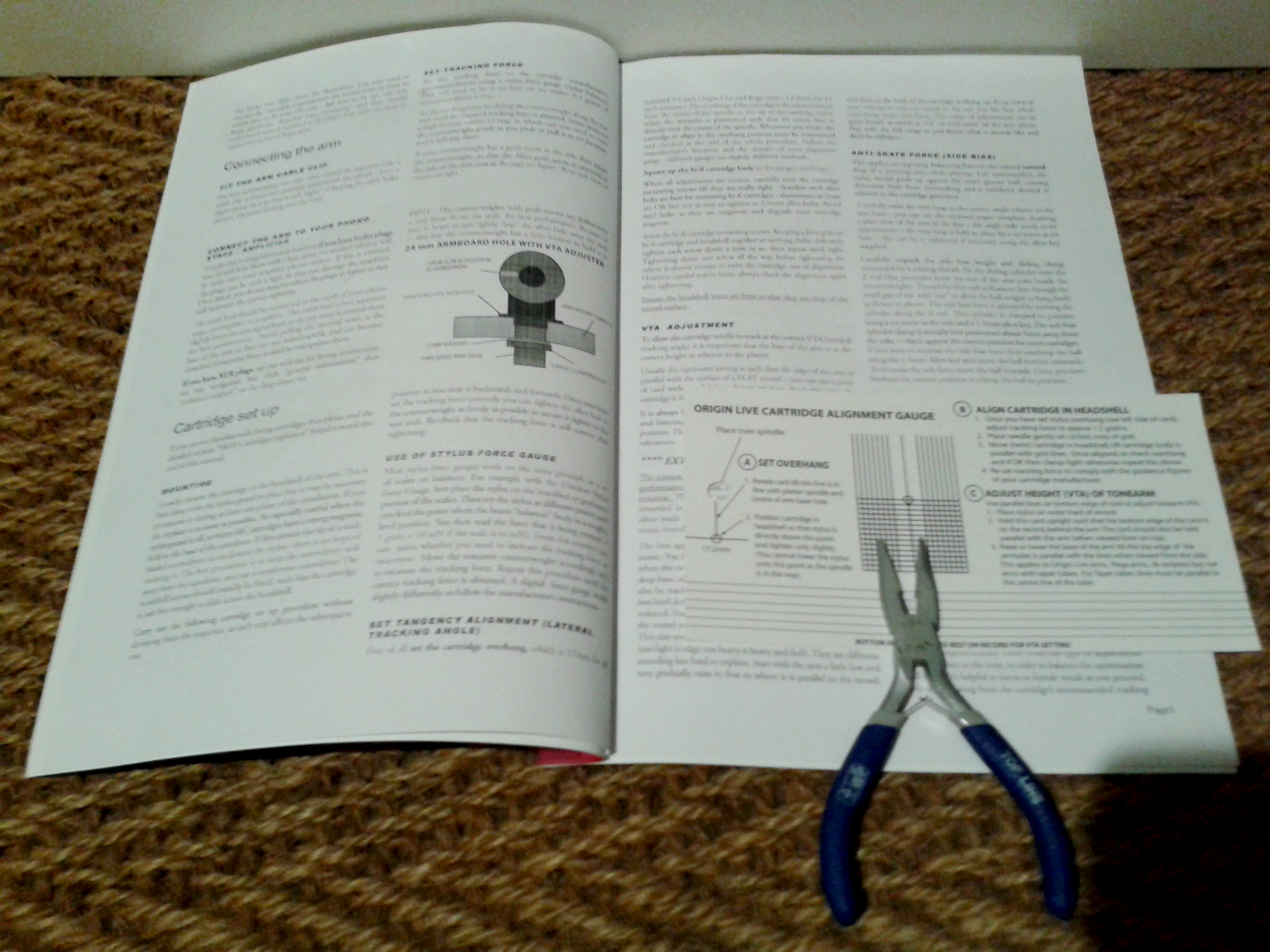

Next thing was the assembling of the new tonearm. The process began by reading the specifications in the manuals, making the new tonearm base and fitting it to the turntable chassis, aligning it with the help a the Cardas disc, replacing the perspex lid, etc.

The final result is excellent, not only aesthetically speaking, but sonically. The sound of the turntable has now more body and depth. The combination of the already good original Thorens TD 318 with the new parts makes the turntable a real winner. A Project Phono Box Ds+ phono preamp completes the vinyl system and makes the combo a first level vinyl playback equipment that delivers hours of the finest music.

A final advice for those who are thinking of purchasing a turntable: consider buying an old Thorens and use with it the medecine of modification. It will give to you great satisfaction.